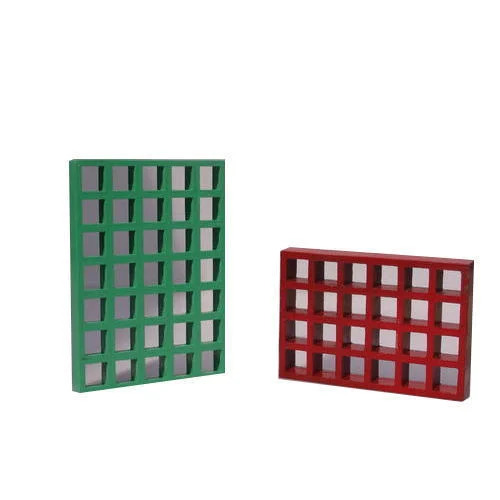

Pultruded Grating

Price 2500.0 INR/ Square Meter

MOQ : 10 Square Meters

Pultruded Grating Specification

- Usage

- Industrial

- Material

- FRP

- Surface Treatment

- Electrophoresis

- Size

- Customized

- Color

- Different Available

Pultruded Grating Trade Information

- Minimum Order Quantity

- 10 Square Meters

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Square Meters Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Pultruded Grating

Pultruded Grating is another type of structural material commonly used in industrial applications, particularly where lightweight, corrosion-resistant, and high-strength properties are required. It offers an exceptional strength-to-weight ratio, making it capable of supporting heavy loads while remaining lightweight. They can be customized to meet specific project requirements in terms of dimensions, mesh patterns, and load-bearing capacities. This is available with different resin options, each offering specific properties to suit various application requirements. Pultruded Grating can be manufactured with UV-resistant additives, ensuring long-term durability and color stability when exposed to sunlight in outdoor applications.

Advanced Surface Treatment for Maximum Protection

Utilizing electrophoresis as a surface treatment ensures exceptional resistance to corrosion and chemical attack, extending the life and maintaining the appearance of our FRP pultruded grating. This advanced process forms a uniform protective layer, making the grating suitable for harsh industrial conditions.

Custom Sizes and Color Options for Your Project

We provide a broad range of sizes and colors to fit your unique requirements. Whether for heavy machinery platforms or walkways, our ability to customize ensures you receive grating tailored precisely for your industrial application.

FAQs of Pultruded Grating:

Q: How is pultruded grating with electrophoresis surface treatment manufactured?

A: The pultruded grating is constructed using the pultrusion process, where continuous strands of FRP are pulled through a resin bath and then through a heated die. The grating is then treated with electrophoresis, creating a durable, uniform coating that enhances corrosion resistance and longevity.Q: What advantages does using FRP pultruded grating with electrophoresis surface treatment offer for industrial settings?

A: This grating provides outstanding strength, chemical resistance, non-conductivity, and a low maintenance surface. The electrophoresis coating further improves durability, making it ideal for environments with exposure to corrosive substances or heavy wear.Q: When should I choose customized FRP pultruded grating for industrial applications?

A: Custom FRP grating is recommended when standard sizes do not meet your specifications or when you require specific features such as color coding, non-slip surfaces, or shapes to fit designated installation areas.Q: Where can I use pultruded grating with electrophoresis surface treatment?

A: This product is suitable for various industrial environments including chemical plants, food processing factories, marine docks, and manufacturing facilities, particularly in areas with high moisture or chemical exposure.Q: What is the purchasing process for customized pultruded grating in India?

A: You can contact us directly as your local distributor, manufacturer, supplier, or trader. Share your requirements regarding size, color, and application. We will guide you through material selection, customization, and delivery arrangements to ensure a seamless procurement experience.Q: How does electrophoresis surface treatment benefit the performance of FRP gratings?

A: Electrophoresis surface treatment adds an extra protective layer to FRP grating, improving its resistance to corrosion, abrasion, and harsh chemicals, making it more durable and longer-lasting in demanding industrial settings.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in FRP And GRP Gratings Category

Molded Grating

Price 2000.0 INR / Square Meter

Minimum Order Quantity : 10 Square Meters

Material : FRP

Color : Different Available

Surface Treatment : Electrophoresis

Size : Customized

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS